A drone flying near a passenger jet is usually cause for strong concern, but hovering a remotely piloted aircraft next to an airliner could become a new safety technique.

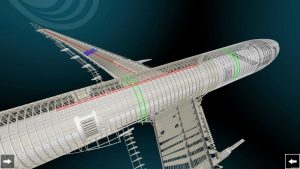

Airbus, one of the world’s largest aircraft manufacturers, has demonstrated how drone technology can be used for aircraft inspections.

At the recent Farnborough Airshow in the United Kingdom, a drone (or, formally, a remotely piloted aircraft, [RPA]) with a high definition camera took 15 minutes to do a visual inspection of the upper part of the aircraft—a task usually requiring two hours using conventional methods.

‘The (RPA) follows a predetermined flight path and takes a series of pictures automatically. All these images, and especially those showing any potential non-quality such as scratches, dents and painting defects, are compiled in a 3D digital model, recorded in a database and then analysed,’ says an Airbus spokesperson.

As well as reducing inspection time and improving data gathering, the addition of RPA technology means a safer working environment for Airbus employees.

‘The use of this new technology offers better working conditions including improving the safety and comfort for the quality inspectors,’ says Nathalie Ducombeau, Airbus head of quality. ‘Operators no longer need to go up on a telescopic handler to perform the visual inspection, sometimes in poor weather conditions.’

‘In addition, picture analysis can be done anytime afterwards and in an office. This data helps improve traceability, prevention, and reduction of damage,’ she says.

Airbus are currently conducting a full-scale industrial test on an A330 aircraft, as well as implementing a range of other maintenance related programs.

Flight Safety Australia previously covered how automated aircraft inspection systems have the potential to make aircraft maintenance safer and more reliable in Robots in the hangar, raising the question of to what extent these automated systems might replace human judgment.