Wire strike rarely offers second chances, which means knowledge, planning and abundant caution are your only defences.

For most private pilots, the best strategy to avoid wire strike is 3 words – don’t go there. However, different words must apply to pilots who make their living flying low – see and avoid.

Ag pilots, survey pilots and owners and operators of aircraft landing areas have no choice but to contend with low-level operations where wire strikes are a perennial risk.

Harley McKillop, chief pilot at Pay’s Air Service in Scone, NSW says preparation and investigation are key to minimising the risk of wire strike for agricultural aircraft.

‘The best way to mitigate risks is to do your checks,’ he says. ‘Even if it’s somewhere you’ve been before, you must get the best third-party information you can. You need to take the time to study the map. Ask the right questions of the grower. Get the best advice you can.’

The next stage of preparation involves on-site inspection and verifying what others have said about the local wires. ‘You can’t just go in with the information that’s been given by a third party,’ McKillop says. ‘ You have to check every part of it yourself.’

For private pilots, McKillop’s advice is blunt: ‘You just shouldn’t be playing around down there. If you don’t need to be there, don’t go there.’

Wire strikes are on the increase. An analysis of key statistics for the past decade shows that, in 2022, wire strikes were 80% above the average number per year. The analysis also shows wire strikes:

- make up 0.5% of the total reported occurrences across all sectors

- comprise 8% of accidents and serious incidents and 5.2% of fatal accidents

- comprise 36% of total aerial work accidents and serious incidents

- occur mostly during aerial work – 73%.

Perhaps most sobering of all, 100% of wire strike fatal accidents involved hitting a wire that was unmarked.

Low flight, high risk

Wire is no respecter of experience – about half of wire strikes have been by pilots with more than 5,000 hours – and very often they hit wires they know are nearby.

McKillop says his 2 wire encounters had a significant factor in common with many aerial agricultural wire strikes. ‘The wires we generally hit are the ones we know about – sadly,’ he says. ‘Every wire I’ve hit I’ve known about. I’ve known where they were but I still hit them.’

Experienced aeromedical helicopter pilot Adrian Park says nearly every pilot operating at low level has a ‘near hit’ story to tell.

‘Whether it’s a wire they didn’t know about, or one they did and got distracted from, each of these pilots narrowly avoided a collision,’ he says.

Wire strikes are the main hazard of low-level flight, and a consistent cause of injury, death and destruction.

‘I’m the same. If it wasn’t for the sharp eyes of my crewie, I would have collected one myself. Such an environment demands our ‘A’ game for sure which means if we are not well trained, don’t have the right procedures, are distracted or unduly stressed and fatigued, we should be giving that low-level job a serious rethink.’

The number of wire strike accidents rises and falls: 2016 was a bad year with 14 accidents, 6 of them involving helicopters. Those 14 accidents resulted in one death and 11 injuries. There were 10 accidents in both 2018 and 2020, while in 2021 and 2022, there were fewer deaths but a higher number of incidents.

During the 2012–2022 decade, 307 wire strikes were reported. Eleven of these involved drones.

- Of the other 296, 217 (73%) occurred while aerial work was being conducted.

- Of the 217 aerial work wire strikes, 194 (89%) occurred during agricultural spraying or spreading.

Robert Feerst, founder of wire strike consultancy Utilities Aviation Services, runs a course on flying in the wire environment. ‘Wire strikes in helicopters are one of the leading causes of hull losses worldwide,’ he says. ‘Sixty per cent of wire strikes result in a fatality. To a low-level flight crew, wire must be classified as an invisible hazard.’

His helicopter-focused course emphasises the vital importance of developing crew resource management (CRM) specifically for low-level operations. ‘The core of low-level CRM is recognising hazards and speaking out at once, regardless of inhibition or perceived rudeness,’ he says.

More than meets the eye

Not all the wire strike occurrences reported during the decade were investigated.

Of the fatal accidents investigated:

- 43% of the wires were known to the pilot but not visually sighted

- 100% were because of hitting an electrical wire that was unmarked

- 75% of the private fatal accidents involved striking wires during unnecessary low-level flight (not on approach or departure).

Of the non-fatal accidents investigated:

- 94% of the wires were not reported as having been marked.

Several factors make wires invisible much of the time, even to a trained and observant crew. These include:

- atmospheric conditions

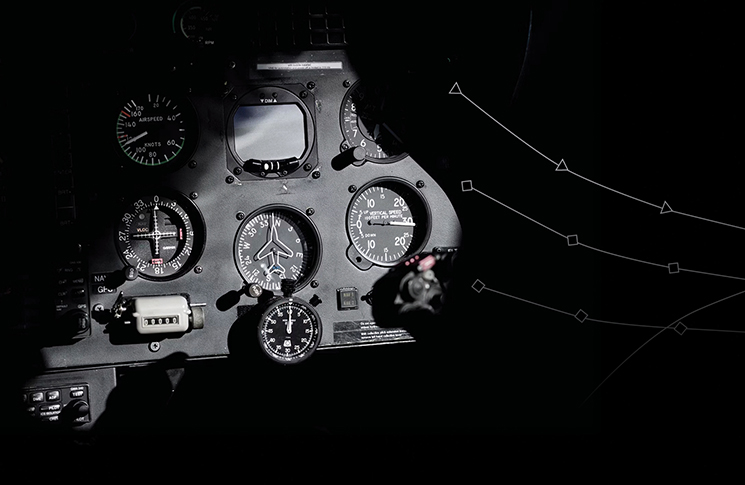

- cockpit ergonomics

- dirt or scratches on cockpit windows

- viewing angle

- sun position

- visual illusions

- pilot scanning abilities and visual acuity

- flight deck workload

- camouflaging effect of nearby vegetation.

Older wires may be difficult to see because their colour often changes with age. Copper wires oxidise to a greenish colour that makes them well camouflaged with vegetation.

Perhaps most sobering of all, 100% of wire strike fatal accidents involved hitting a wire that was unmarked.

Some electricity transmission towers, including in the NSW Hunter Valley, are actually painted green to blend in with the environment. This is soothing for residents, but not for pilots.

A wire that is perfectly visible from one direction may be completely invisible from the opposite. The exact location of specific wires may change throughout the day because of fluctuating ambient temperatures, which may cause wires to sag or tighten. Even on a cloudless day, the blue of the sky can change to reveal, or hide, wires. Long spans of wire may be blown by the wind, with displacements of tens of metres for wires crossing valleys.

Then there are optical illusions, including:

- high-wire illusion: When you are looking at 2 parallel wires from 200 metres or more away, the highest wire will appear further away when it may not be

- phantom-line illusion: A wire running parallel to others can become camouflaged.

Look up and live

Australia has comprehensive regulations including minimum height requirements, the requirements for ratings and endorsements for both low flying and aerial work operations, as well as requirements for the marking of obstacles (including wires) in the vicinity of certified aerodromes.

Educational, promotional and awareness products are available for pilots and landowners, detailing the risks posed by wires. These are provided by the Aerial Application Association of Australia, electrical infrastructure companies, the ATSB and CASA.

Over recent years, the Aerial Agriculture Association of Australia has worked to reshape the Australian Standard on the marking of powerlines. The association has developed a human factors training course, and worked with powerline companies to develop mapping and marking systems and make them available to pilots and business owners.

It has launched a powerline safety program to encourage power companies to improve aviation safety, as well as encouraging aviation businesses and rural landholders to improve safety.

Echoing research conducted by the ATSB, the association says that while training and professional development play a significant role in preparing pilots to manage the risks associated with low-level operations around powerlines, there are 2 key initiatives that can improve safety: the provision of mapping information on powerline networks and the marking of powerlines.

The resources that electrical infrastructure companies provide about specific wire hazards (pre-flight) and visual detection of wires (in-flight) vary from state to state and from company to company. The ‘Look up and Live’ mapping is highly regarded. Some subsidies are also available for landowners to mark electrical wires.

The invisible enemy

While there has been a significant reduction in wire strikes over the past 50 years, they continue to pose an ongoing risk to aviation operators, particularly those conducting (but not limited to) aerial work operations and most significantly during aerial application activities.

Fatalities due to wire strikes are disproportionately affecting sectors other than aerial work. This is due to more robust, higher-powered aircraft typically being utilised in aerial work (and aerial application), compared to private and recreational operations. This means a wire hit by an aerial work aircraft is more likely to separate from the pole before causing significant damage to the aircraft.

Some electricity transmission towers, including in the NSW Hunter Valley, are actually painted green to blend in with the environment.

Being aware of wires relies on information being available and the pilot knowing where to find it. However, the quality of the data varies significantly from state to state.

Queensland and NSW have tools for pilots to assess if wires exist in their area of operation or along their planned flight route, whereas other states do not. Aerial work and EMS pilots are making extensive use of the existing tools whereas private and recreational pilots are less likely to use them for pre-flight planning.

In 2011, a feature in Flight Safety Australia noted, ‘Wire strike avoidance requires much more than running through a checklist’. That remains true.

If flying in a wire environment can be avoided, don’t go there. For those whose work demands operating in a high-risk wire environment, seek training and access the resources available.

Be aware of local information and the atmospheric conditions around you. Wire is a barely visible hazard that poses a continuing risk to flight safety.

Resources

- Watch a video about wire strikes on our YouTube channel, CASA Briefing.

- Get a wire strike poster from our online store. It’s listed under ‘Flight planning’ and it’s free – just pay postage and handling.

- For more on flying in non-controlled airspace, visit the pilot safety hub.

- Look up and live

- ATSB – Wire strikes: a technical analysis

- Aerial Application Association of Australia