A safer ramp isn’t the stuff of fiction, reckons Alwyn Brice, but there is still a long way to go.

When Nick Careen, IATA’s Vice President, Airport, Passenger, Cargo and Security, spoke recently at the 32nd IGHC event in Madrid, he had three key points to make. Members, he urged, must continue to put safety first; there must be an implementation of global standards; and the sector should look to accelerate the speed of innovation and process modernisation.

No-one present could have argued with any of those laudable requests. Airport authorities, carriers and handlers all see it in their best interest to operate in an environment that is risk-free and one that allows its staff to return home safely at the end of each shift. It used to be thought (at least, that was the word on the ramp), that ground handling was one of the most dangerous professions in the world, up there with construction work. But recent league tables (based on US data) suggest that the logging and fishing sectors post the worst statistics, with aircrew, grounds people, farmers and roofers all appearing in the top ten. There is no sign of ramp work—so is the sector finally shrugging off its negative image?

Towards standardisation

In this, IATA would dearly like all its members to be singing from the same hymn sheet, and rightly so. To enable this, protocols for handlers have been developed. Under the aegis of ISAGO, audits can be carried out to ensure a handler is conforming to a carrier’s standards. Further, the introduction of IGOM has seen the distillation of best practice into one definitive manual for standard operating procedures. These are positive steps, but it does not get away from the fact that practically every airline knows best when it comes to something as basic as coning and chocking an aircraft—and that’s where the IGOM gets thrown out of the window. Some in the sector argue that if consensus on such a simple task as that cannot be obtained, then there is no hope for the bigger picture. Yet IATA and the sector stakeholders know that standardising practice lies at the very heart of any advance in safety.

A history lesson

Parking a beltloader or a set of steps (or indeed a catering truck or a PRM lift) up against an aircraft without quite touching it is akin to parallel parking your car next to a kerb, with a few centimetres to spare. You might do it once—but try repeating the action, over and over again. That’s what the sector faces—and that’s the action that the operator has to execute, day after day.

Enter technology, something that can ease the problem of the GSE/aircraft interface. Innovation and progression may sit awkwardly within the GSE sector, and indeed, over the last 20 years, it can be argued that there has been little true advance in the realm of safety on the ramp. But the recent developments in the area of autonomous ramp vehicles is, to my mind, a real breakthrough, and something that could truly reshape the sector—and slice that huge annual ground damage bill. Frankly, this advance has experienced a lengthy gestation period. Back in 2005, Air France recorded an incident when a crew member suffered a tragic accident on passenger steps. This prompted a thorough investigation that led to its order for new JBT AeroTech loaders being equipped with enhanced safety technology, some of which was (then) unknown in the sector. It was arguably the first step forwards for safer GSE—but sadly, it took an accident to prompt it. Safety barriers, telescopic stairs, front sensors and a governed approach speed were stipulated features that were all well ahead of their time.

US technology strides

Today, that same US company is pioneering an autonomous loader. This has to be seen to be fully appreciated, but the loader is capable of automatic approach and can ‘dock’ at three inches from the fuselage door, without human prompting. The secret lies in the technology employed. Relying on Lidars (Light Detector and Ranging sensors, which visually scan in slices), optical cameras, ultrasonics and ‘last resort’ bumpers, the Ranger is equipped with two separate systems: one helps navigation from its location to the aircraft, whilst the second governs the precision docking process. The Ranger is programmed to locate an open hold door and can detect this orifice from 15 metres away. A 360° viewpoint camera mounted on top, together with short distance side sensors and three ground level sensors, take care of other vehicles’ presence, or even that of cones or staff on the ramp.

JBT is looking to trial the autonomous Ranger later this year—and best of all, this technology can be retrofitted to both existing Ranger and Commander models.

French and German progress

In its efforts towards a safer ramp, electric tractor supplier Charlatte has worked with Navya, an important name in the design of autonomous passenger shuttles. This latter has developed virtual driver technology as well as obstacle avoidance systems and localisation programmes—everything, in fact, that is desirable for a ramp-based vehicle. Five Lidars are employed around the tractor, two cameras give front and rear vision, real-time GNSS (kinematic) antennae are attached and there are odometry measuring devices on the wheels. The tractor is thus able to detect a moving object and, after digesting the information, can either carry on, brake lightly or stop completely. If it detects something preventing its forward progress, it halts and sounds a klaxon.

Will the sector leap straight to autonomous? Charlatte’s spokesperson alludes to the problem of integrating such with the current ramp. Technology and mindset are still challenges to be overcome—and that for the foreseeable future, at least, there would be an ‘active’ passenger carried in the cab. In certain sensitive airport areas this would be vital.

Charlatte adds that by the end of the year two units will be on trial: at an industrial site and a French airport. All being well, series commercialisation is on the cards for next year.

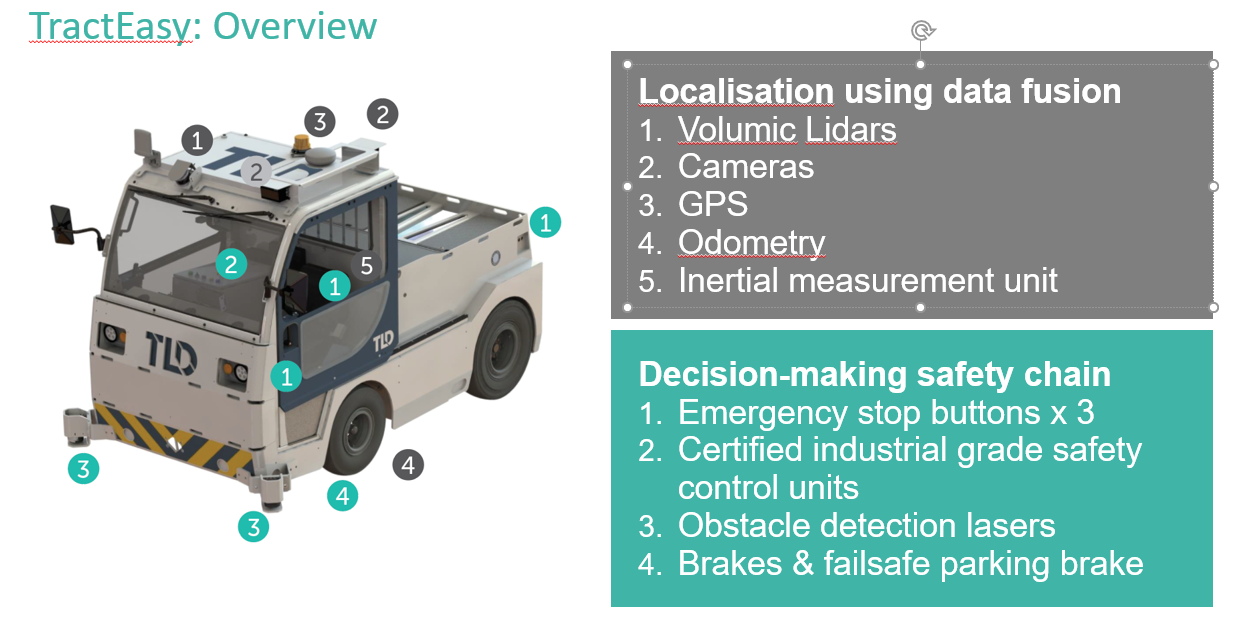

The other France-based player is TLD, which is partnering with EasyMile, another pioneer in autonomous vehicle technology and smart mobility solutions. Key to progress here is the development of software to automate transportation platforms without the need for a dedicated infrastructure.

According to TLD, a roadmap is already being followed, with the TractEasy the harbinger: it will be followed by beltloaders and steps. Already available, TLD’s Aircraft Safe Docking System (ASD) allows for governed speed reduction as the GSE approaches the aircraft (the speed is dropped to 5 kph); this falls to 0.7 kph as the vehicle closes. The TractEasy is fitted with an array of sensor technology (see diagram)—some of these applications have been developed in-house, since there was nothing available in the marketplace. Such technology permits the desired autonomy and the tractor will stop or decelerate if its ‘brain’ detects an issue ahead, such as too narrow a gap. A built-in, fail-safe system allows full control to be regained in the event of an emergency.

TLD is also of the opinion that for the moment, an on-board ramp worker will be desirable. Further ahead, however, it is confident that this back-up could be dispensed with, thereby giving selected GSE full autonomy. As for commercialisation, this is already underway, with initial contracts signed.

Finally, Mulag, the German tractor manufacturer, has also been involved in this segment, working with SAE to come up with a driverless tractor that again relies on sensors and cameras for obstacle avoidance.

Taking steps

Mallaghan’s autonomous passenger steps were trialled with low cost carrier easyJet back in 2017. Steps, along with conveyor belts, are the chief culprits in terms of ground damage, so anything that can be done to address their negative image is welcome.

Mallaghan’s steps work with sensors that lock on to targets that need to be affixed to the cargo door’s periphery. The manufacturer feels that this is a safer methodology than relying on a gaping void for the locking on procedure. Although international standards recommend that a gap of 4–5 inches (10–13 centimetres) between the step lip and the fuselage is satisfactory, these steps can approach accurately to within 2–3 inches (5–8 centimetres). At nearly 10 feet (3 metres) wide, the steps benefit from sensors that allow an overall width of over 14 feet (4 metres), thus giving the steps some leeway either side before safety dictates that the GSE stops. The final approach speed to the target is very slow, in accordance with safety protocols.

Currently, the manufacturer is more focussed on developing driver assistance technologies, deeming that the autonomous research is something more for the foreseeable future—yet a future that will definitely come.

Drilling down to the basics

Lastly, on the basis that towing baggage dollies around the ramp is both inefficient (the tractor has to wait until each dolly is full, for example) and dangerous, in June 2019 the International Airline Group announced an industry first: the autonomous dolly.

Aurrigo, a UK autonomous vehicle specialist, was approached by IAG to achieve this, and trials began in March. The dolly employs Lidar and GPS technology and has become a self-driving, electric vehicle that promises to increase the speed of loading and unloading luggage. It has run successfully at T5 in Heathrow; and since BA has 900 dollies sited there, mechanising the fleet brings obvious benefits. Aurrigo fell back on its Pod Zero passenger carrying vehicle experience to achieve this novel roll-out.

In conclusion, science-fiction is fast becoming science-fact. Autonomous road vehicles have already been extensively trialled and it’s clear that the technology holds more than mere promise. The confines of the ramp offer an ideal arena for this technology that once proven, will help to eradicate that element of human error that dogs the sector.

A safer ramp is, I’m convinced, a coming reality.

Comments are closed.