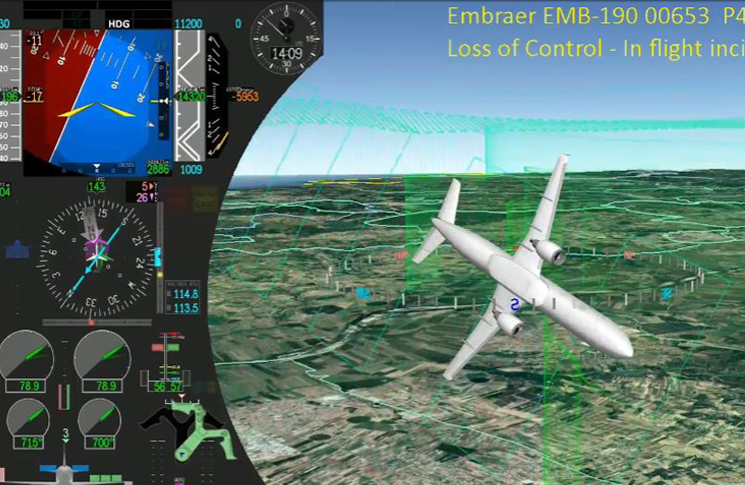

An aileron rigging error led to the extraordinary and frightening flight by an Embraer ERJ 190 over Portugal last November, Portugal’s Aviation Accidents Prevention and Investigation Department has said in a preliminary report. The single aisle 97-seat airliner encountered flight control difficulties soon after take-off at 1331, local time on 11 November 2018 and the crew declared a Mayday.

The aircraft belonged to Kazakhstan’s national airline Air Astana and was on a ferry flight to the country’s largest city, Almaty, after undergoing C-check maintenance in Portugal. There were three pilots and three engineers on board.

In the words of the Portuguese report, ‘Immediately after take-off, with adverse meteorological conditions, the crew felt that the aircraft was not responding adequately to the commands, developing oscillatory wing movements.

In the words of the interim report, ‘the performed trajectories caused the aircraft and the technicians on board to sustain intense G-forces, as well as the aircraft complete loss of control for some moments at multiple instances’.

‘All on board were physically and emotionally shaken,’ the report says, although there was only one minor physical injury—to an engineer’s leg.

Faced with flamboyantly unstable responses to control inputs but no warnings of any aircraft system failures, the crew reverted the fly-by-wire aircraft’s controls to direct law (selectable by switch on the pedestal of the ERJ-190), in which the flight control module is removed from the control system and control surfaces respond in proportion to human inputs on the yoke and pedals.

This improved the situation considerably without restoring normal operation and considerable difficulties persisted in roll control. The crew responded by minimising roll inputs wherever possible.

The crew was able to recover sufficient control of the aircraft and divert to Beja, 125 km south-east of Lisbon. The aircraft landed on its third approach about 15:36.

The preliminary investigation says a modification carried out in accordance with an Embraer Service Bulletin had changed a cable routing support near rib 21 of the aircraft. This change made it harder to understand the maintenance instructions and spot reversed aileron cables.

‘During maintenance, the engine-indicating and crew-alerting system (EICAS) displayed a caution message: “FLT CTRL NO DISPATCH”. This meant that one of the components of the flight control system had failed. Troubleshooting activities by the maintenance service provider, supported by the aircraft manufacturer, lasted 11 days. However, the ailerons’ cables reversal was not identified in this period,’ the reports says, noting that the incorrect rigging was not identified in the pre-take-off flight controls checks.

Comments are closed.