Future aircraft structural inspections may become as simple as shining a sophisticated ‘torch’ at the wing, based on research being done in the US. Staff at Rice University, in Texas, have developed a way to tell the strain on an aircraft structure using a handheld reader that shines a light on carbon fibres and measures the response.

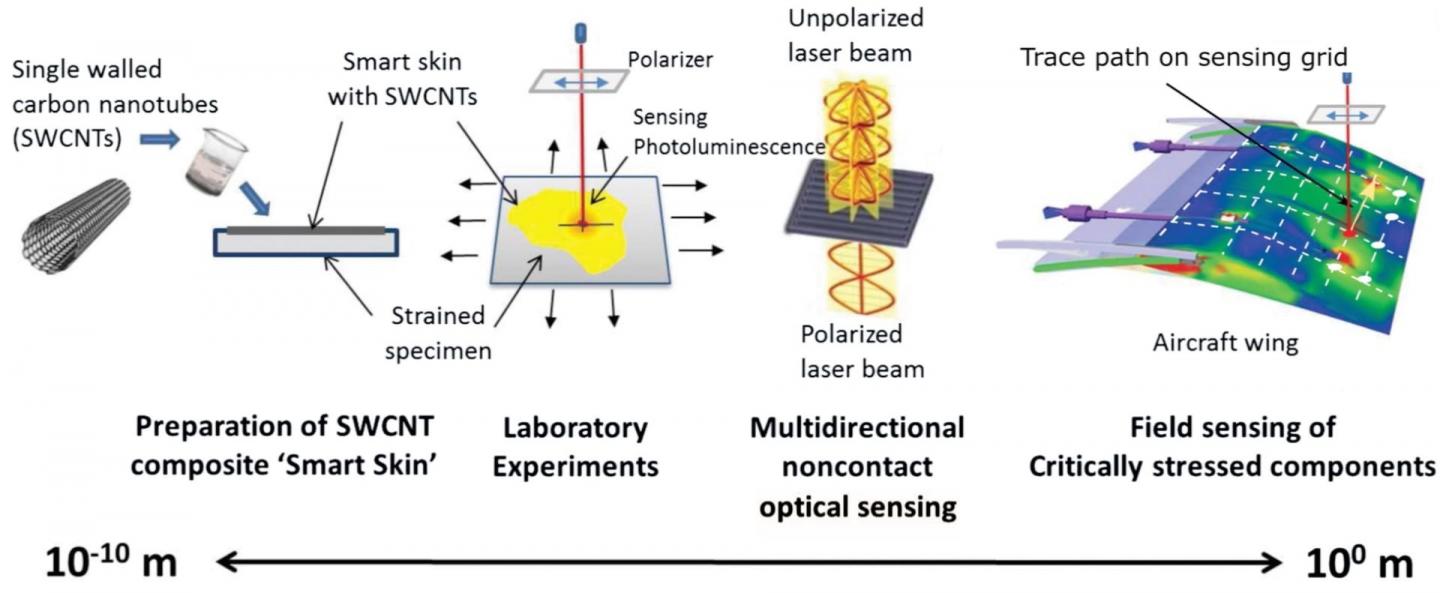

So-called ‘smart skin’ has been under development by engineering and chemistry researchers at Rice University in Texas, US, since 2012. A recent paper describes encouraging progress.

In 2002, Rice chemist Bruce Weisman discovered that single-wall carbon nanotubes fluoresce, rather like how a white shirt glows under ultraviolet light. Later the researchers discovered that stretching a nanotube changes the color of its fluorescence.

Strain, or deformation, in the surface shows up as changes in the wavelengths of near-infrared light emitted from the film. The results could be used to show whether structures such as bridges or aircraft have been deformed by stress-inducing events or regular wear and tear.

The latest report describes ‘smart film’ that can be spray painted on to a structure and can reveal strain in any direction and location.

The two-layer film is only a few microns thick, a fraction of the width of a human hair, and barely visible on a transparent surface. ‘In our initial films, the nanotube sensors were mixed into the polymer,’ engineering researcher Satish Nagarajaiah said. ‘Now that we’ve separated the sensing and the protective layers, the nanotube emission is clearer, and we can scan at a much higher resolution. That lets us capture significant amounts of data rather quickly.’

The researchers are working toward developing the next generation of the strain reader, a camera-like device that can capture strain patterns over a large surface.