A tangle of misinformation about engine bay flammable fluid flexible hoses needs clearing up

Dangerous ideas are not always outrageous. Sometimes they arise out of simple misunderstandings, turgid language or the unfortunate situation where a subject is regarded as too boring for serious attention. The dangerous ideas surrounding engine bay flammable fluid flexible hoses tick all three of these boxes.

The dangerous idea CASA airworthiness inspectors have noticed is a belief that some types of medium pressure rubber hoses can be used in engine bays without additional fire resistant protection.

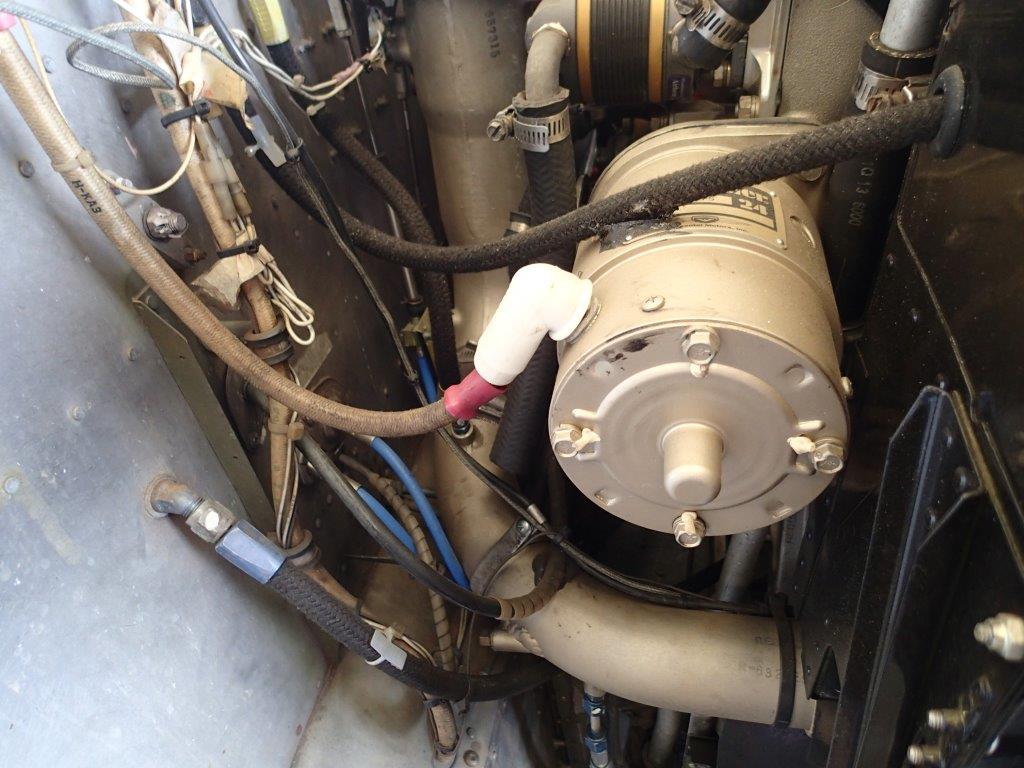

Some examples are below.

This belief centres on Aeroquip’s 303 hose. Aeroquip, a division of Eaton Corporation, is a major supplier of hoses and end fittings to the aviation industry. The other major manufacturer is Stratoflex, a division of Parker Hannifin Corporation. Both companies supply medium pressure hoses suitable for use in fuel and oil supply lines to aircraft engines. A large portion of the general aviation piston engine fleet uses hose assemblies, made from products from these suppliers, to supply fuel and oil to their engines.

There are two issues. The first is maintenance companies manufacturing hoses under their manufacturing in the course of maintenance (MITCOM) privileges without appropriate data detailing the correct materials to use. The other issue arises when the maintenance company uses hose manufacturer specifications and design specification data, instead of aircraft manufacturer’s data. The hose manufacturer specifications and design specification data can be difficult to interpret and understand.

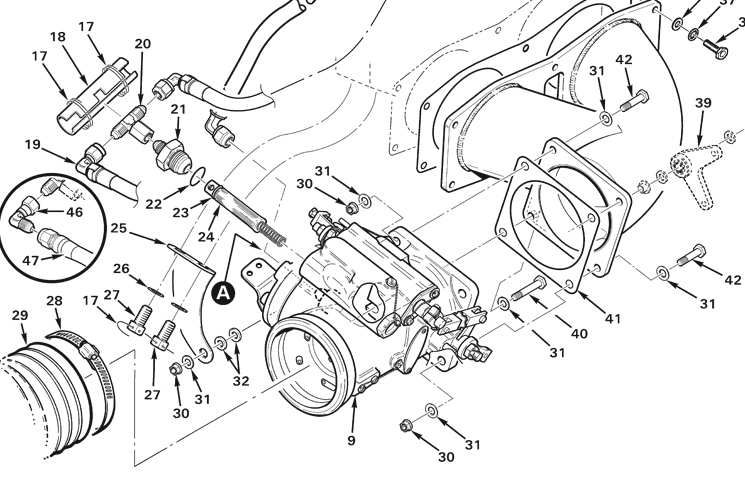

On the first point, which is key to solving the issue, when manufacturing a part under MITCOM, a maintainer must use appropriate data. The data must include dimensions, materials, design standards and any test requirements. Most manufacturers of general aviation aircraft do not provide this information in the standard maintenance manuals. A manufacturer’s illustrated parts catalogue will normally provide a number for the whole hose assembly. A couple of examples are below. The part number for the hose may give some indication of the size of the hose, but little other useful information you could use to make a hose.

What is a maintainer to do? There are several options:

- purchase an original part from the aircraft manufacturer or from a third party manufacturer that has approval to make the replacement part

- if you have MITCOM privileges, contact the aircraft manufacturer and request the information needed to make the hose yourself

- ask an approved design organisation to create suitable data to use so you can make the part.

The last option would be in the form of an engineering order (EO) that authorises replacement of the manufacturer’s hose with one made in accordance with the EO.

These processes can be costly and time consuming. This is probably why some maintenance organisations have chosen to use generic hose design data and hose manufacturer’s material specifications. While this is good information, it is not approved data for manufacturing a specific hose assembly. This information can also be very confusing, with each manufacturer presenting data in different formats and in different places.

This is probably the reason why some people believe Aeroquip 303 hose can be used in an engine bay without any fire resistant coating, while Stratoflex 111 hose cannot. Stratoflex provides a good document on fire resistance testing for its hoses. Right at the start of the document it clearly states that hose assemblies used in a fire zone must be fire sleeved. A fire sleeve is a jacket installed over the 111 rubber hose to increase its fire resistance to an appropriate standard.

Aeroquip provides information on the specifications of its 303 hose and the material standard. It also provides information on its fire sleeve product, but does not make a statement about when a fire sleeve is required.

There is a general design standard used for most general aviation fuel and oil hoses. That standard is Technical Standard Order (TSO) C53a.

This design standard is broken into several sections. One section describes types of fire resistant and non-fire resistant hoses and their operating environment. The confusing part is that while this section refers to fire resistant and non-fire resistant types of hoses, it doesn’t say how fire resistance is achieved. Without further research, you might conclude that a Type C hose is fire resistant in the normal operating environment of a piston engine bay, about 120 degrees Celsius. Then if you read the Aeroquip 303 hose specification, it also says the hose is suitable for an operating environment up to 121 degrees (being American, it says 250 degrees Fahrenheit). Quickly join the dots and you might jump to the conclusion that Aeroquip 303 hose is fire resistant when installed in an engine bay where the operating temperature is up to 121 degrees, or 250 Fahrenheit.

It is not until you read further into TSO 53a that you find fire testing requirements, and a sentence buried in a paragraph that says you may need to use a fire sleeve to achieve fire resistance compliance.

Now let’s add more confusion. Aeroquip says the 303 hose meets the standard MIL-DTL-8794. This manufacturing standard is another lengthy and technical read. It covers types of material used in construction of the hose, operating temperatures and pressures, fittings used in hose assemblies, dimensional conformity and testing requirements and performance standards, among many other technical details. The standard doesn’t talk about fire resistance at all. It is not until you get to the notes on page 23 that there is a sentence, again buried in the middle of a paragraph, which says that hose assemblies utilising MIL-DTL-8794 standard rubber hose fitted with a proper fire sleeve may be used

in fire zones.

Stratoflex makes the requirement to use fire sleeves on hoses in fire zones easy to find. Finding the same information for Aeroquip hoses requires reading, and most importantly, understanding lengthy and highly technical design and manufacturing standards. This is probably where the myth about Aeroquip 303 originated—hard to find, read and understand data.

So let’s be clear: the Aeroquip 303 hose on its own does not meet suitable fire resistant standards for use in a fire zone.

CASA Airworthiness Bulletin 02-006 Issue 2, of 2016, discusses maintenance practices for flexible hoses. Section 3.6 says engine compartment hoses must be fire resistant.

The myths of the fire resistant Aeroquip hose has led to some maintainers manufacturing hoses without suitable, approved data for the hose they are making. You must have approved data for the actual hose or have data to manufacture an approved alternative hose.

Comments are closed.